When it comes to designing or commissioning a warm air heating system, one technical term that often causes confusion is Air Off Temperature. What does it mean? Why does it matter? And how does it impact real-world performance? In this article, our expert Brett Smith breaks down the concept, explaining how Air Off Temperature plays a critical role in system design, comfort levels, and heating coverage—especially in large commercial and industrial spaces. Whether you’re an installer, consultant, or end user, understanding this metric is key to getting the most out of any warm air heating solution.

Air Off Temperature refers to the temperature of the air as it leaves a warm air heater. In simple terms, it’s the output temperature of the air after it has passed through the heat exchanger and is discharged into the space being heated.

This temperature is typically measured just inside the warm air unit’s discharge outlet and is influenced by factors such as burner output, airflow rate, the condition of the heat exchanger, and the temperature of the incoming (ambient) air.

Air off temperature plays a crucial role in both comfort and system efficiency. If the air is too hot when it leaves the unit, it can cause discomfort—especially in areas directly exposed to the airflow. If it’s too low, the system may struggle to heat the space effectively.

More importantly, monitoring or specifying the correct air off temperature helps to:

Ensure proper heat distribution throughout the building

Avoid overheating or underheating in different zones

Protect the system’s heat exchanger from thermal stress

Balance comfort levels with fuel consumption

In modern systems, some controls allow for adjustment of the air off temperature to suit seasonal needs or specific operational demands.

For most commercial and industrial warm air heaters, air off temperatures typically range from 40°C to 60°C, depending on the application and environmental conditions. This range strikes a balance between quick heat-up times and safe, comfortable airflow for a variety of spaces, including warehouses, workshops, retail environments, and showrooms.

Air throw refers to the distance the heated air travels from the heater outlet before slowing down and mixing with the surrounding air. In high-ceilinged or open-plan buildings, achieving sufficient throw is essential to ensure that warmth reaches occupants and key working areas.

A higher air off temperature increases the thermal energy in the airstream, allowing it to travel further before dissipating. However, if the temperature is too high, the warm air may rise too quickly, leading to stratification—where heated air collects at ceiling level rather than where it’s needed.

To counter this, heating designs often include destratification fans or heat recovery systems that help push warm air back down, improving comfort and reducing waste. A well-balanced system considers air off temperature, airflow velocity, and discharge angle to optimise throw without compromising efficiency.

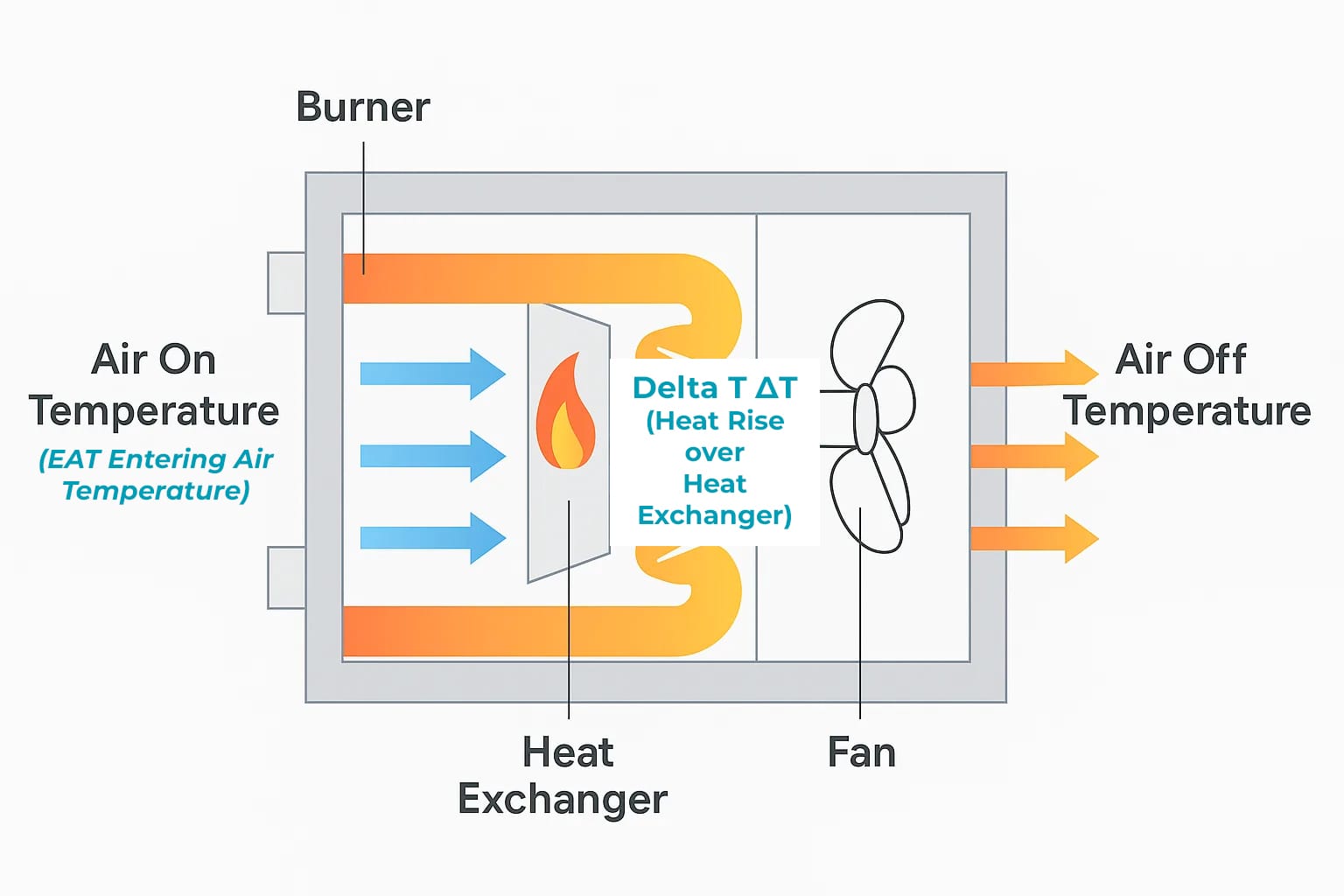

It’s also important to understand Air On Temperature—also called Entering Air Temperature (EAT)—which is the temperature of the air entering the heater before it’s warmed. As shown in the diagram, the air is heated as it passes through the heat exchanger.

The difference between the air on and air off temperatures is known as Delta T (ΔT). This ΔT represents the heat rise over the heat exchanger and is a key measure of the system’s thermal performance.

For example, if air enters the system at 15°C and exits at 45°C, the ΔT is 30°C. This temperature rise is critical in system design to ensure the heater can deliver sufficient thermal output to meet real-time heating demands.

Powrmatic warm air heaters—such as the LX range—are designed to deliver consistent, controlled air off temperatures, thanks to advanced burner control systems and high-efficiency heat exchangers. This leads to steady, comfortable warmth throughout the heated space and reduces energy waste.

With smart controls, building managers can fine-tune air off settings to match occupancy, usage patterns, and external temperatures—creating better control and long-term cost savings.

Air off temperature is a vital part of warm air heating system design. It affects everything from energy use and occupant comfort to air throw and heat distribution. When properly managed, it ensures the system delivers steady, effective heating without excessive fuel consumption or hot and cold spots.

Whether you’re specifying a new system or upgrading an existing one, understanding air off temperature—and its relationship with airflow and building layout—can help you achieve better, more cost-effective results.